RETURN TO TREVORMCTAVISH.COM

Calgary, AB, Canada - March 2013

In 1965 de Havilland Canada flew the first DHC-6 Twin Otter - arguably the best airplane ever created for the unique demands of STOL flying. De Havilland Canada built 844 Twin

Otters (series -100, -200 and -300) between 1965 and 1988. In 2008, Viking Air purchased the type certificate and began production on a modernized series -400.

Thanks to a friend working at Viking, I was able to tour their Calgary production and flight testing facility.

Assembly and initial test flying of the -400 Twin Otters is done in Calgary, AB. Here we see the sub-assemblies of the fuselage being put together. The cockpit is made by Viking Air in Victoria, BC while the mid-fuselage panels comprised of the belly and window belts are prepared by Field Aviation in Calgary. (Trevor McTavish)

Here is one of the panels containing the rear fuselage doors that Viking Air assembles in Calgary. This is the only component manufacturing work done in Calgary. (Trevor McTavish)

Now we see the final fuselage being assembled: the Viking cockpit, the Field centre section, the Viking doors and the tail cone from Fleet Aircraft in Fort Erie, ON. (Trevor McTavish)

Once they're removed from the assembly jigs, the fuselages receive their first runs of wiring (background) and are mated to the landing gear (foreground). You can see one of the changes in the -400 series; the escape hatch in the upper fuselage behind the wing has been removed. (Trevor McTavish)

You can see just how clean a factory Viking Air is running. Every tool, every bench, every fixture has its place neatly marked on the shop floor. Even the garage bins have their own dedicated spots.

Although Viking doesn't advertise who they're building each airplane for, they do mark it with the flag of its destination country. This particular Twin Otter is serial number 879, as the number on the tail indicates. (Trevor McTavish)

Serial number 878 has reached the stage where its been mated to a pair of wings, flight controls and stabilizers from Viking Air in Victoria. The composite doors, a major change for the series -400, are manufactured in Quebec by FDC Composites of Saint-Jean-sur-Richelieu and Delastek in Grand-Mere, QB.

From here, the Twin Otters will be moved over to the second bay of the hangar and into final assembly and flight testing. (Trevor McTavish)

Upgrading the Twin Otter really was a Canada-wide project. Cascade Aerospace in Abbotsford designed the composite parts while Calgary's Amtech Aeronautical designed the glass cockpit that really sets the -400 Twin Otters apart from their older brothers. (Trevor McTavish)

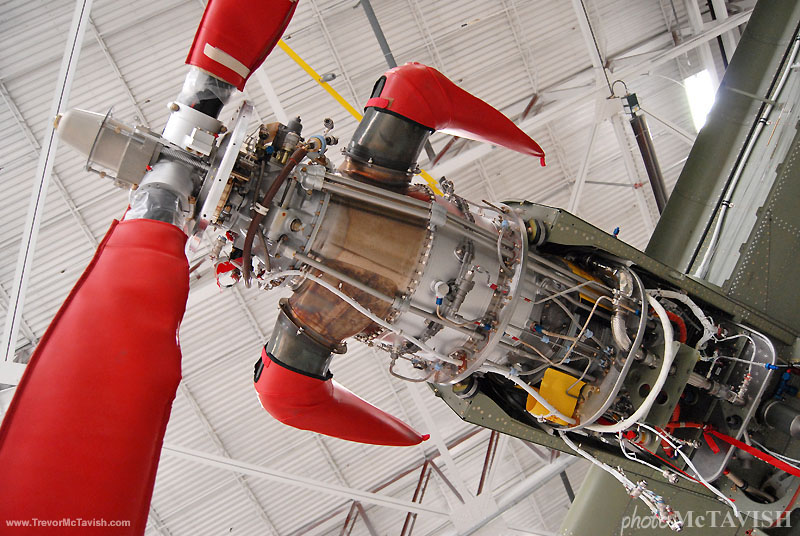

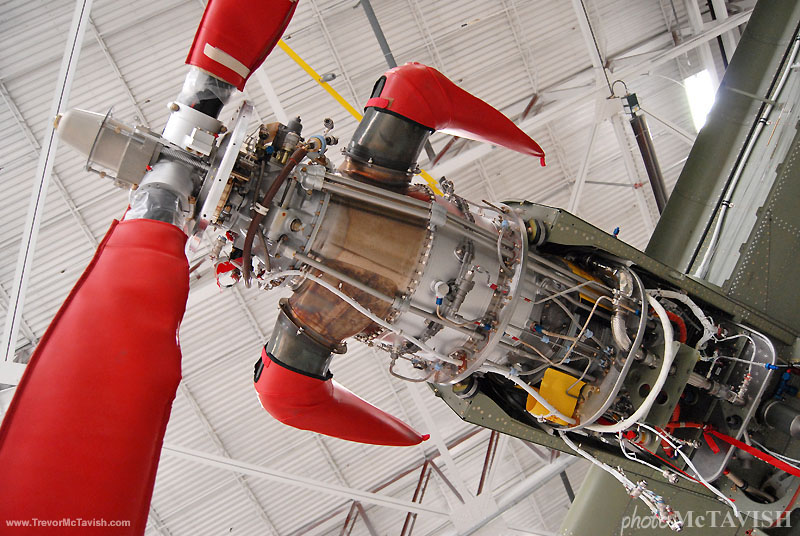

Another major change was upgrading the Pratt & Whitney Canada PT6 engines to the -34 model. The PT6-35 is an option. Each of these comes fresh from the Pratt & Whitney Canada factory in Lethbridge, AB. (Trevor McTavish)

With most of the cockpit instruments and engine components installed serial number 877 approaches its place in the flight test spot. There's a major 'push' or move between assembly stations every several weeks, and at the time of my visit it took 12 weeks to transform 877 from a collection of parts to a (almost) flying airplane. (Trevor McTavish)

Here we can see one of the other options this Twin Otter customer has opted for - the tip tanks out on the end of the wings. Most of the wires on the end rib are for the pump and indicating systems. (Trevor McTavish)

After almost three months serial number 876 is finally ready to take to the skies. There will be a series of ground runs to test the systems, then low and high speed runs down the runway before this Twin Otter finally becomes an airplane with its first flight. Then, there's another 4 to 5 hours of flight testing to confirm the airplane's handling and the EFIS (Electronic Flight Instrument System). (Trevor McTavish)

On this particular day, 876 was being rolled out for one last engine run before flight testing began. I believe this Twin Otter will be heading to Vietnam where that country's Navy has ordered six DHC-6-400s for maritime patrols and search and rescue. (Trevor McTavish)

Once Calgary has completed its portion of the flight test program each Twin Otter is sent to Spokane, WA, for paint, then to Viking in Victoria where the interior is installed. Once the finishing work is complete, the planes go through a final series of flight test items before finally being handed over to their new owners. (Trevor McTavish)

RETURN TO TREVORMCTAVISH.COM